The tractor trailer's air brakes let out that familiar pitch indicating it was safe to roll open the back door to reveal it's contents. One hundred neatly stacked cardboard boxes lay inside. The bounty of our pre-order hailing all the way from Thailand. It was the most exciting day of the year at the shop and we were eager to get our first look at some of the inaugural shapes.

We unloaded the contents at a feverish pace because that's what you do when your delivery truck is choking the traffic to a single lane along Pine Street and your driver is too busy taking his smoke break to help out. The last box was carefully laid on the ground, the delivery slip was signed, and the box cutters were unsheathed. Time to rip into some cardboard.

Repetition has a way of communicating a consistent message that can be hard to recognize initially. We were building a rhythm and efficiency in our process to free each board from its coffin. In the process we experienced the inescapable language and reality of packaging. The cardboard itself is rugged and thick providing necessary padding for the fragile contents within. But that's never enough. Additionally you'll also find a perfectly shaped rectangular brick of expanded polystyrene (EPS) foam at either end to protect the nose and tail from sloppy handlers, erratic drivers, and every other known and unknown threat these beauties will face on their journey.

Packaging is a necessary evil to guarantee the safe arrival of the works of art in each box. It's easy to play out the cost/benefit schema in your head as you contemplate the end of life of each of these foam bricks and whether their short life was justified in the pursuit of damage-free delivery. Surely the cost to produce and the cost of disposal is substantiated by the multi-thousand dollar product they're designed to protect, right? But what are the real costs? Are there alternatives that provide the same value with less downside? Do the blocks have to lay to rest in the dumpster? What should the end of life plan of a styrofoam block look like?

I'm not quite sure how much time had passed as I pondered the plight of the blocks. I only came to when my colleagues reminded me that we were engaged in a friendly competition of who could open more boxes before lunch arrived. Still, I was intrigued by the question of what to do with all these blocks and the other hard-to-recycle packing materials used by the crew at Cobra to deliver these boards to us safely.

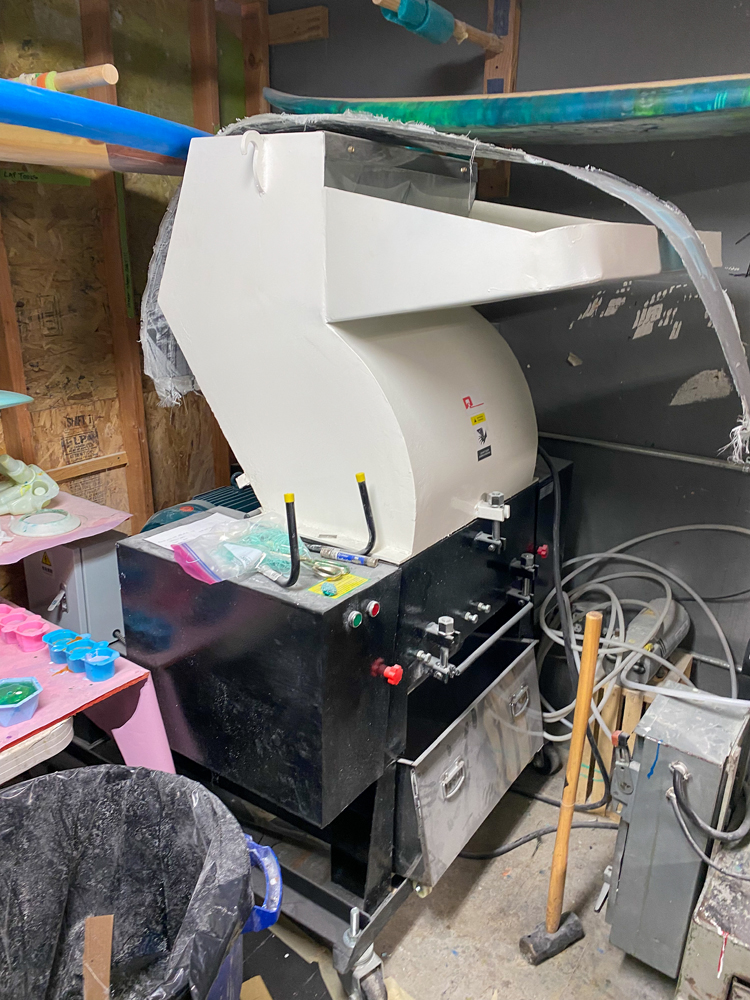

Sometime after I'd inhaled my second fish taco, I walked back out to the parking lot and began making my plan to give these blocks a second life. We had built a small shaping room next to the shop to tinker with shapes and repair dings. This room would be the new home and project site for our very own "waste to waves" story and these essential packaging materials were going to play the leading role.

The experience of turning these otherwise discarded pieces of foam into an array of different boards and shapes revealed all kinds of lessons. The first was realizing just how much work goes into shaping and glassing a board by hand. It's a ton of work. Ever wonder why it takes forever to get your shaper to finish that custom board you ordered? Now I know why. Mad respect to all of you out there doing this for a living each and every day. The second lesson had to do with choices in materials and the inherent risks associated with some of these known carcinogens. Everyone appreciates a good arts and crafts project, particularly one where the end result is rideable and saves a bunch of foam from a landfill in the process. But what about health and safety? What exactly am I breathing and how toxic is this little room I've stuffed myself into for countless hours? What are all the big board builders doing to solve for these issues and how do they reconcile with the risks and hazards involved? Surely there must be a better way. I got curious and started down the rabbit hole. That's when I discovered the high energy highly motivated shaper and all around good vibes character of Ryan Harris and Earth Technologies.

You can find Ryan on Instagram. That seems to be his back yard. He posts a new video almost every day from within the shop doing his thing with a style and charisma that only comes from those who truly love what they do. Ryan is a kick ass shaper. There's no doubt he's got the gift for his craft. But he's equally gifted as an entertainer in the way he presents his genuine stoke and enthusiasm for shaping, glassing, and most importantly for saving the planet. Ryan is not only committed to building the best boards possible, he's doing so with the promise of being the first (and currently only) waste-free surfboard production company using the greenest products available. That's a pretty heavy claim.

How does he do it?

Ryan is genuinely concerned about the environment - a by-product of his Pacific northwest heritage as an outdoorsman. When he moved to LA to pursue the art of board building, his niche for living sustainability followed suit. "Every product that has ever been made has a waste stream. How can I make my industry better than when I came into it." Ryan is on a mission to demonstrate to the greater surfing community that there are greener and more sustainable surfboard production methods that deliver the same performance as traditional boards. Fortunately for him, he isn't alone.

Rey and Desi Batanao are the dynamic brothers, founders, and minds behind Entropy Resins - the first bio-based resin on the planet. Entropy participates in the USDA BioPreferred Program having developed and manufactured the first epoxy product certified under the USDA. Put simply, these guys are working to make things better while making things better for the environment. Sure they are both passionate about snow, surf, and skate, but they also have the engineering and entrepreneurial chops to develop a cutting edge product that works while scaling a company in the process.

The brothers are the sons of Diosdado Batanao, a Philipine success story heralding from modest beginnings as the son of a rice farmer to a Silicon Valley three-time start up veteran in the computer science and electrical engineering industries. Rey has a PhD in computational biology and is currently working on end-of-life solutions for a wide variety of composite materials including surfboards and snowboards through his new company, Connora. Desi has a masters in material science and engineering from UC Berkeley and is still the man in charge at Entropy. The Entropy culture was formulated from a passion for being outside with an appreciation for technology and how it can impact the world. Desi and Rey knew they were onto something big that could benefit the surf industry and were on a mission to find a shop to adopt an eco-board mentality and a commitment to building boards.

The brothers knocked on every door of every poly board shop they could find until the day they met Ryan. "Hey we're looking for a shaper who's interested in setting up a shop committed to sustainability and environmentally safer products, you interested?".

That simple question led to the beginning of a new venture that would become the origin of the eco-board movement. Ryan jumped in head first becoming the first shaper under the Entropy Surf Shapes brand and went to work. The new team no sooner connected with Kevin Whilden of Imagine Surf who was looking for a production company to launch a new initiative of sustainable boards that they would refer to as their "eco-board" line. These were the early years of sustainable thinking in surfboard production, but each member of the team deeply believed in the necessity and urgency to start thinking differently about how surfboards should be produced. The team's passion and determination paired with critical and effective engineering paved the way to a movement that quickly caught the attention of the biggest brands in the industry.

There was some solid momentum happening in the adoption of eco-boards. The misconception of sacrificing performance for sustainability was in the rear view as brands like Lost, Channel Islands, and Fire Wire were getting on board. Ryan and his growing team of shapers and glassers were at the forefront of the movement connecting with the early adopters of eco-board brands helping them to prototype and create each brand's first generation of eco-boards. Innovation was out pacing regulation, as it often does, when a great concept is paired with impeccable timing and growing consumer demand.

The need to define what it means to be an eco-board and distinguish between the multi-dimensional layers of process, materials, and footprint created Sustainable Surf and their science-based independent third party accreditation program. "Here is our simple vision: if we can change our surfboards to physically embody the ideals of sustainability, then we can change ourselves too. If we take these steps now, we can still ensure a long, sustainable future for the culture of surfing, as well as for our amazing watery planet that makes it all possible – it’s really that simple." Ryan was the first shaper ever to earn the Gold standard certification from Sustainable Surf.

Sustainable Surf not only accredits the shapers and board builders working to clean up their production process, they're also working tirelessly to protect and restore ocean health by shifting people to a highly desirable, low-carbon, "Deep Blue" lifestyle.

"The ocean is the best tool we have to fight climate change" says Sustainable Surf's Brett Giddings. "Anyone can make a difference in restoring coastal ecosystems by supporting programs like SeaTrees that are designed to help offset carbon footprints through the reforestation of mangrove forests."

SeaTrees is an online portal built for ocean lovers who struggle to find ways to do their part to address climate change. Their goal is to plant one million trees on behalf of the global surfing community each year.

One of the most visible and outspoken ambassadors of their lifestyle is Starboard athlete and author, Zane Schweitzer. Zane is the prodigy of Hoyle Schweitzer, one of the foremost innovators of the windsurfer. Hoyle grew up with the likes of Grubby Clark and Hobie Alter in an era when polyurethane (PU) foam was king. Since then, Zane has used his influence as an athlete to move the industry away from the toxicity and harmful effects of PU and polyester resin to a more sustainable deep blue future for our sport.

From the beginning, Zane's primary sponsor Starboard has led by example committing to reduce their carbon footprint by becoming net positive across their entire supply chain, sequestering carbon through the planting of a mangrove for every board they sell, and leading the composite board building industry by using the most environmentally friendly production practices possibile. In 2016 Starboard teamed up with Parley for the Oceans to re-think and re-engineer any and all petroleum-based materials, accessories, and packaging from their product line. All formerly petroleum-based inserts were replaced with bio-based alternatives, board bags were redesigned to use recycled PET (rPET), and all plastic packaging was replaced by paper. In addition, Starboard encouraged all other board builders to follow suit knowing that meaningful change could only happen if the entire industry participated.

Starboard supplies Zane with all the SUPs and windsurfers he needs to ride, compete, and test. But Zane was still in search of a shaper that could deliver eco-friendly short boards to round out his quiver. That's when the introduction was made to Ryan Harris via the boys at Sustainable Surf. "Zane was a lot of fun to work with. That guy has some crazy high energy", said Harris.

Schweitzer and Harris went to work building boards that lasted longer than traditional polyurethane boards while protecting the environment in the process. The two of them shared a like-mindedness that made the process feel fluid and natural, complimenting the talents that both shaper and surfer brought to the project. "Your epoxy (EPS) board is gonna outlast your poly board two fold", says Ryan. "I'm a big guy and I break PU boards all the time. Epoxy boards just last longer which means fewer of them end up in a landfill and more of them can be recycled".

We're all trying to be more conscious of what we discard knowing the ugly truths of what our disposable economy does to the planet. The raised consciousness of circularity and the concept of designing reclamation and end-of-life thinking into a product from the onset are just now becoming more and more popular. We're seeing a spike in environmental, social and governance (ESG) investments across the globe as consumers and manufacturers place more emphasis on doing the right thing when it comes to protecting the environment and being smarter about how we source materials.

It's nice to know that the surf industry is participating in this wave of change considering our dependence on clean oceans to preserve our sport, culture, and well being. This same level of consciousness is what made me pause when staring down at that pile of foam blocks and wondering what their immediate future looked like.

For the last 3 to 6 months, I dedicated as much free time as I could to gluing, shaping, sanding, and glassing these blocks into five custom niche boards that I always wanted to have, but couldn't justify purchasing. My limited knowledge as a shaper and amatuer skills with a sander was still enough to produce some rideable equipment that may lack in performance, but make up for it in the satisfaction of being built with reclaimed and bio-based materials from my own sweat equity.

We all need to be more resourceful when it comes to managing raw materials with an emphasis on repurposing, recycling, and upcycling existing products to promote circularity. That is one of the reasons we created See Change Sessions on H2O - a sustainability conference focused on using business as a tool for good bringing pro athletes, artists, film makers, CEO's, technologists and activists from all backgrounds to confer on solutions for protecting our oceans. Please join me in watching and participating in the See Change Sessions Eco Board discussion hosted by panelists Ryan Harris, Brett Giddings (Sustainable Surf), Desi Banatao (Entropy Resins), and Tasmin Chilcott (Starboard) moderated by Zane Schweitzer. This two-day virtual event kicks off on August 18th, 2021 at seechangesessions.com and is aimed to further develop the thinking, contacts, innovation, and future of board building. Hope to see you there.